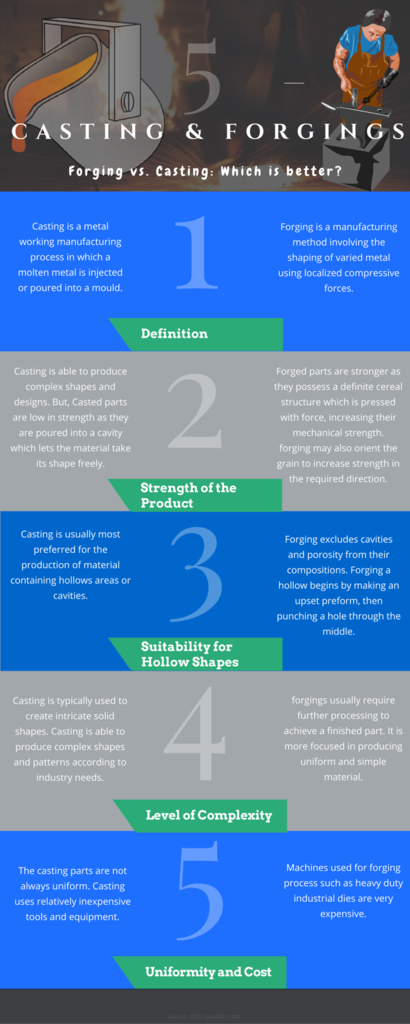

Forging Vs. Casting: Comparing Casting and Forging Manufacturing Process

There are thousands of casting and forging companies in India and worldwide. They manufacture a vast variety of forging and casting components according to market's requirements. Here, we discussed about casting and forging methods.

Forging and casting are two very different manufacturing process. Moreover, Both are metal-working process usually used in varied industries in India and worldwide. They are often not restricted to metals.

Why Use Castings ?

We use castings for a vast range of components as well as wear parts that are too large. In this process, the main advantage of casting is no real upper size limit in casting weight. Moreover, elements are often less expensive than forge dies.

Why Use Forgings ?

Forging provides uniformity of structure as well as composition. Forged steel components are stronger than castings due to the grain flows of the steel are altered, conforming to the shape of the part.

Advantages of Forgings

- The tight grain structure of forgings making it mechanically strong.

- Will handle impact better than castings

Conclusion

Forged parts had a 26% higher tensile strength than the cast parts. For More information about forging, you can contact to prominent forging exporters in India.